The E300 Electronic Overload Relay, produced by Rockwell Automation, is a cutting-edge device designed for motor protection in industrial applications. This manual provides essential guidance for safe installation, configuration, and operation, ensuring optimal performance and compliance with safety standards.

1.1 Overview of the E300 Electronic Overload Relay

The E300 Electronic Overload Relay is a state-of-the-art device designed for motor protection in industrial automation systems. It features a modular design, advanced communication capabilities, and real-time diagnostic tools. The relay provides robust overload protection, ground fault detection, and voltage monitoring. With a user-friendly interface and configurable parameters, it ensures precise control and monitoring of motor operations. Its compatibility with Allen-Bradley systems makes it a versatile solution for integrated industrial applications.

1.2 Importance of the Manual for Installation and Operation

This manual is crucial for the safe and effective installation, configuration, and operation of the E300 Electronic Overload Relay. It provides detailed instructions to ensure compliance with safety standards and optimal performance. The manual includes troubleshooting guides, parameter configurations, and diagnostic tools, helping users maintain reliability and efficiency. Adhering to the guidelines prevents potential malfunctions and extends the relay’s lifespan. It serves as an essential resource for technicians and operators to maximize the device’s capabilities in industrial automation systems.

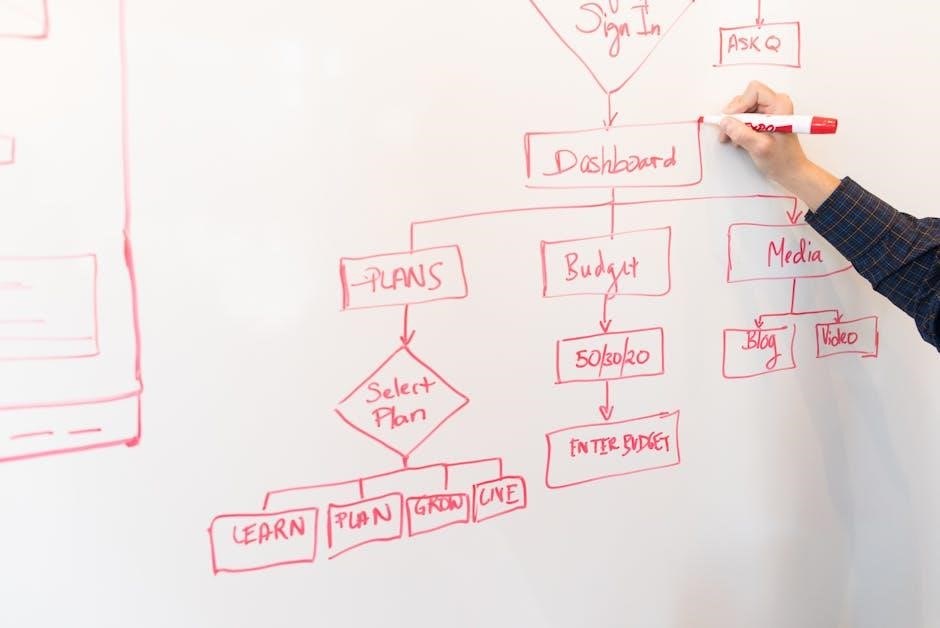

Installation and Wiring of the E300 Relay

The E300 Relay installation begins with accessing the dip switches by sliding the front cover. Proper wiring and setup, as outlined in the manual, ensure optimal functionality and safety.

2.1 Pre-Installation Checklist

Before installing the E300 Relay, ensure all components are included and undamaged. Verify the correct voltage rating matches your system. Follow safety guidelines, including de-energizing circuits and wearing PPE. Familiarize yourself with the manual to understand setup requirements. Check the environment for compatibility, avoiding extreme temperatures and humidity. Ensure communication modules are compatible if network integration is planned. Proper preparation ensures a smooth and safe installation process, minimizing potential issues during operation. Always refer to the manual for specific prerequisites and safety measures.

2.2 Step-by-Step Wiring Instructions

Begin by disconnecting power to the motor and control circuits for safety. Connect the motor supply lines to the relay’s output terminals, ensuring proper polarity. Next, wire the control circuit, connecting the start/stop buttons and auxiliary contacts as per the control logic. Configure the Dip switches according to the manual to set the operational parameters. Finally, verify all connections for accuracy and test the relay by energizing the circuit to ensure proper operation. Always refer to the manual for specific wiring diagrams and configurations.

2.3 Common Wiring Mistakes to Avoid

When wiring the E300 relay, avoid reversing the input and output terminals, as this can cause system malfunction. Ensure all connections are secure to prevent loose contacts, which may lead to intermittent operation. Incorrectly configuring the control circuit can disrupt motor control logic. Always refer to the wiring diagrams provided in the manual to avoid misconnections. Additionally, never connect power to the control circuit without de-energizing the motor supply to prevent potential electrical hazards and damage to the relay.

Configuration and Setup of the E300 Relay

The E300 relay requires precise configuration to ensure proper operation. Use dip switches to set basic parameters and establish communication settings for seamless integration with industrial systems.

3.1 Understanding Dip Switches and Their Functions

The E300 relay utilizes dip switches to configure basic settings. These switches are accessible by sliding down the front cover. Key functions include enabling Admin Mode by setting switches to 0, 0, 0, and configuring overload protection, communication, and operational parameters. Proper configuration ensures optimal performance and compatibility with industrial systems. Always refer to the manual for specific switch configurations to avoid errors and ensure reliability. This section provides detailed guidance on interpreting and setting dip switches for precise control of the E300 relay’s functionality.

3.2 Configuring Relay Parameters for Optimal Performance

Configuring the E300 relay parameters ensures tailored protection and efficiency. Parameters such as trip levels, timing, and curves can be set using the diagnostic station or communication modules. The attached spreadsheet in the manual details each parameter, enabling precise adjustments. Proper configuration enhances motor protection, reduces downtime, and aligns with specific application needs. Regular reviews and updates of these settings are recommended to maintain optimal performance and adapt to changing operational requirements. This step is crucial for maximizing the relay’s effectiveness in various industrial environments.

3.3 Establishing Communication Settings

Configuring communication settings for the E300 relay enables seamless integration with industrial automation systems. Install compatible communication modules such as DeviceNet, Ethernet/IP, or other supported protocols. Assign an IP address to the relay for network connectivity. Use the diagnostic station or software tools to configure settings like baud rate and node address. Ensure proper network configuration for remote monitoring and control. Verify communication compatibility with Allen-Bradley PLCs or SCADA systems. Test the connection to confirm data transmission accuracy. Proper communication setup is essential for real-time monitoring and efficient system operation.

Diagnostics and Troubleshooting

The E300 relay features advanced diagnostic tools for real-time monitoring and fault detection. Use the diagnostic station to identify and resolve common fault codes, ensuring optimal performance and minimal downtime.

4.1 Using the Diagnostic Station for Real-Time Monitoring

The E300’s diagnostic station offers real-time insights into the relay’s status and connected equipment. It displays critical data such as current, voltage, and temperature, enabling quick identification of potential issues. Users can monitor operational parameters, view fault codes, and track historical data to preemptively address problems. This tool enhances troubleshooting efficiency, reducing downtime and ensuring smooth operation. Regular monitoring through the diagnostic station is crucial for maintaining system reliability and performance.

4.2 Identifying and Resolving Common Fault Codes

The E300 relay generates specific fault codes to indicate operational issues, such as overload, ground fault, or communication errors. These codes are displayed on the diagnostic station, enabling quick identification of problems. Referencing the manual, users can interpret each code and follow recommended steps for resolution. Common faults often relate to wiring issues or configuration errors. Addressing these promptly ensures minimal downtime and prevents potential damage to connected equipment. Regular reviews of fault codes help maintain system reliability and performance.

4.3 Advanced Troubleshooting Techniques

Advanced troubleshooting involves analyzing real-time data from the diagnostic station and interpreting fault codes to identify root causes. Users can access detailed parameter settings to refine configurations and ensure optimal performance. Utilizing communication protocols, the E300 relay integrates with industrial systems, allowing for remote monitoring and advanced diagnostics. Regularly reviewing system logs and leveraging Rockwell Automation’s technical resources can enhance troubleshooting efficiency. These techniques enable users to address complex issues swiftly, minimizing downtime and ensuring reliable operation.

Protection Features of the E300 Relay

The E300 Relay offers comprehensive protection against overloads, ground faults, and voltage fluctuations, ensuring enhanced motor and system safety. Its advanced surge suppression capabilities further safeguard equipment from power spikes, providing reliable operation in industrial environments.

5.1 Overload Protection Mechanisms

The E300 Relay incorporates state-of-the-art electronic overload protection, designed to detect excessive current and prevent motor damage. It features adjustable overload settings, enabling customization to suit specific motor requirements. The relay monitors motor current in real-time, ensuring operation within safe limits. Upon detecting an overload, it trips to protect the motor and connected equipment. This mechanism enhances system reliability and prevents potential failures. The overload protection is integral to the E300’s functionality, ensuring efficient and secure operation in industrial environments.

5.2 Ground Fault and Voltage Protection

The E300 Relay includes advanced ground fault and voltage protection features to ensure motor and system safety. It detects ground faults through precise current monitoring, isolating the motor to prevent damage. Voltage protection safeguards against overvoltage and undervoltage conditions, maintaining stable operation. These mechanisms work seamlessly with overload protection, enhancing reliability and preventing potential hazards. The relay’s robust design ensures accurate detection and response, protecting equipment from voltage fluctuations and ground-related issues, thus maintaining system integrity and operational efficiency in industrial settings.

5.3 Power Protection and Surge Suppression

The E300 Relay incorporates robust power protection and surge suppression capabilities to safeguard connected equipment from electrical disturbances. It is designed to handle voltage spikes, power surges, and transient events, ensuring reliable operation in harsh industrial environments. The relay’s surge suppression features protect against damage caused by electrical storms or power grid fluctuations. Enhanced power protection ensures uninterrupted performance, maintaining system stability and preventing premature wear on motors and associated machinery. This advanced functionality makes the E300 an essential component for industrial automation systems requiring high levels of reliability and fault tolerance.

Integration with Industrial Automation Systems

The E300 Relay seamlessly integrates with industrial automation systems, including Allen-Bradley, PLC, and SCADA. It supports networked environments, enhancing operational efficiency and system control capabilities.

6.1 Compatibility with Allen-Bradley Systems

The E300 Relay is fully compatible with Allen-Bradley systems, ensuring smooth integration with Rockwell Automation platforms. It supports seamless communication and control, enhancing industrial automation efficiency. The relay’s design allows for easy setup within Allen-Bradley environments, enabling advanced monitoring and diagnostics. This compatibility ensures that users can leverage the E300’s features while maintaining system coherence and performance.

6.2 Integration with PLC and SCADA Systems

The E300 Relay seamlessly integrates with Programmable Logic Controllers (PLCs) and SCADA systems, enabling advanced monitoring and control. Real-time data exchange ensures optimal performance and protection. Compatible communication protocols like Modbus, BACnet, and Ethernet/IP facilitate smooth integration. This capability enhances system reliability and provides detailed operational insights, making it easier to manage industrial automation processes effectively.

6.3 Using the E300 in a Networked Environment

The E300 Relay excels in networked environments, offering enhanced communication capabilities for industrial automation. With support for protocols like Modbus, Ethernet/IP, and BACnet, it integrates seamlessly with other devices. Real-time monitoring and control enable efficient system management. Networked setups allow for remote diagnostics and firmware updates, ensuring optimal performance. Scalable and secure, the E300 supports industrial IoT applications, making it a reliable choice for modern, interconnected systems.

Maintenance and Best Practices

Regularly inspect connections, clean components, and update firmware. Ensure optimal operating conditions to prevent overheating and extend lifespan. Follow guidelines for electrical safety and environmental compliance.

7.1 Routine Maintenance Checks

Perform routine inspections to ensure the E300 relay operates efficiently. Check for loose connections, dust buildup, and wear on terminals. Verify that all dip switches are correctly configured. Clean the relay and its environment to prevent overheating. Inspect the power supply and communication cables for damage or interference. Update firmware periodically to maintain optimal performance and security. Regularly review diagnostic data to identify potential issues before they escalate. Ensure all environmental conditions, such as temperature and humidity, remain within specified limits for reliable operation. Schedule these checks to prolong the device’s lifespan and maintain system integrity.

7.2 Best Practices for Long-Term Reliability

Adhere to manufacturer guidelines for installation and operation to ensure long-term reliability. Regularly update firmware and software to maintain performance and security. Avoid exposing the relay to harsh environmental conditions beyond its specifications. Use surge protectors to prevent damage from power spikes. Train personnel on proper handling and troubleshooting techniques. Document all maintenance and configuration changes for future reference. By following these practices, you can maximize the lifespan and reliability of the E300 relay in industrial automation systems.

7.3 Environmental Considerations for Installation

Ensure the E300 relay is installed in an environment that adheres to its specified operating conditions. Avoid exposure to extreme temperatures, humidity, or corrosive substances. Install the relay in a clean, dry, and well-ventilated area to prevent dust or moisture buildup. Avoid direct sunlight or heat sources, as this can cause overheating. Use surge protectors to safeguard against power spikes. Mount the relay securely to prevent vibration damage. Always follow environmental guidelines provided in the manual to ensure optimal performance and longevity of the device.